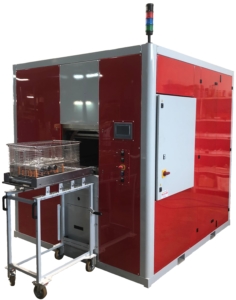

RH machines are aqueous cleaning systems designed to meet the demand for high specification cleaning of batches of small components, or larger items with complex structures.

Components, located inside dedicated stainless steel baskets or fixtures, are cleaned using a high pressure, hydrokinetic washing action or total immersion with ultrasound and vacuum. Depending on the nature and sensitivity of the components, the basket or fixture can be rotated through 360O (either continuous or counter rotation), oscillated, or held static.

The RH range comprises of a number of models, based on basket size and throughput requirement. They are completely closed-circuit, with continuous filtration of the washing and rinsing baths and separation of oily residues through closed-circuit oil separators. Drying takes place in a closed or vacuum circuit according to the materials of construction of the components being treated.

In designing the machines, particular attention was paid to:

- Easy handling of loading and unloading operations according to ergonomic principles.

- Optimization of operating costs by adopting innovative heat recovery systems.

- The use of high quality stainless steel components.